MULTI PLATE SCREW PRESS

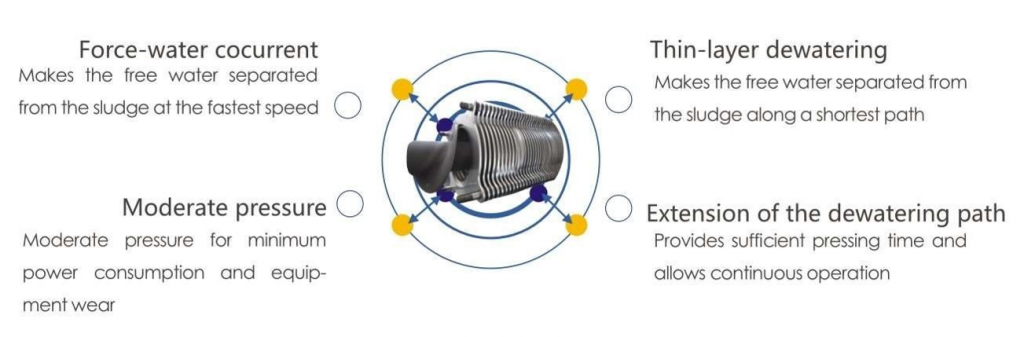

The Multi-plate Screw Press developed by Techase utilizes the dewatering principles of force-water homo-direction,thin-layer dewatering, proper pressure, and extension of the sludge dewatering path.

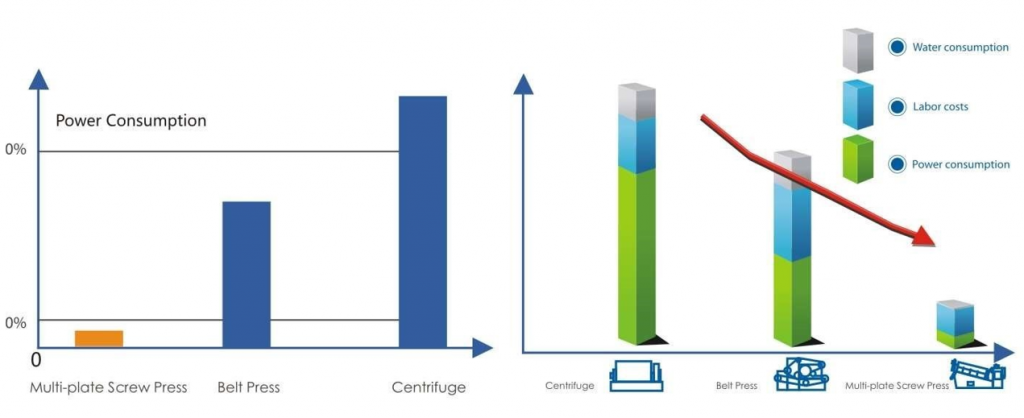

The new equipment, more advanced than the traditional dewatering equipment which is easily blocked, unsuitable for low-concentrated sludge and oily sludge, of high consumption and difficult to operate, well eliminate these problems and are of higher efficiency and power saving.

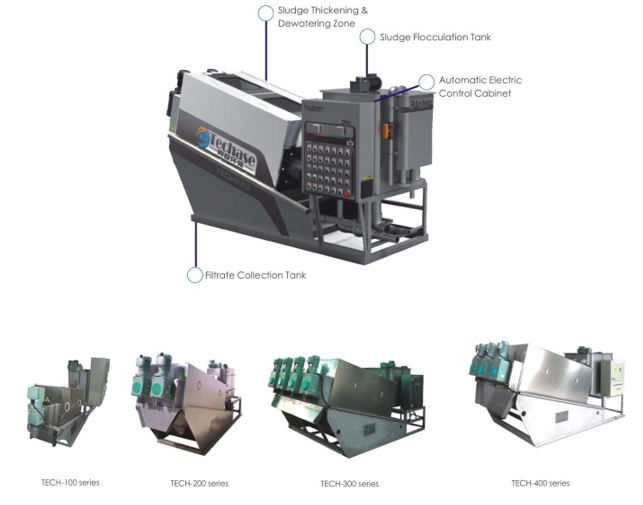

Multi-plate screw press, which is controlled by the electric control cabinet, allows automatic continuous operation of sludge flocculation, thickening, dewatering, and filtrate discharging.

Our Research

Inch Techase, as the industry leader and first brand of Multi-plate Screw Press, have the strongest R&D capability, most application cases, largest production capacity, richest product lines, and highest recognition from professional users.

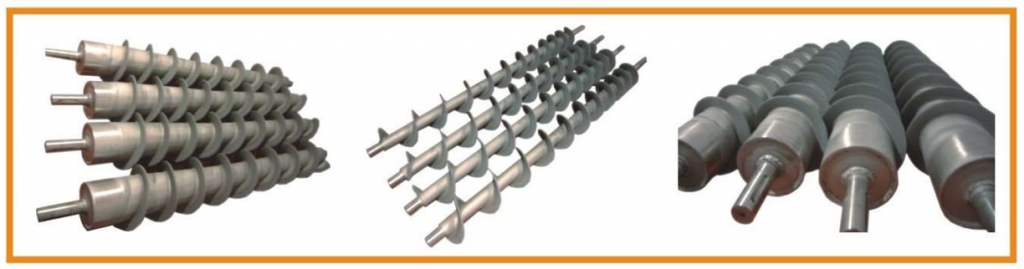

Under the cooperation with Tongji University, Techase built the finite element model according to ANSYS screw shaft pressing theory, which basically solved the problems of the product design, technical innovation, and equipment operation. On the basis of the advanced model,

Techase successfully developed the following significant technology innovations:

- 400 Series Screw Shaft (Industry First)

- Wear-free type of Multi-plate Screw Press (Industry First)

- Special screw shaft for Sludge Thickener (Industry Only)

- Special screw shaft and machine for inorganic material (Industry Only)

- Special screw shaft and machine for petrochemical, pectin, paper industry (Industry Only)

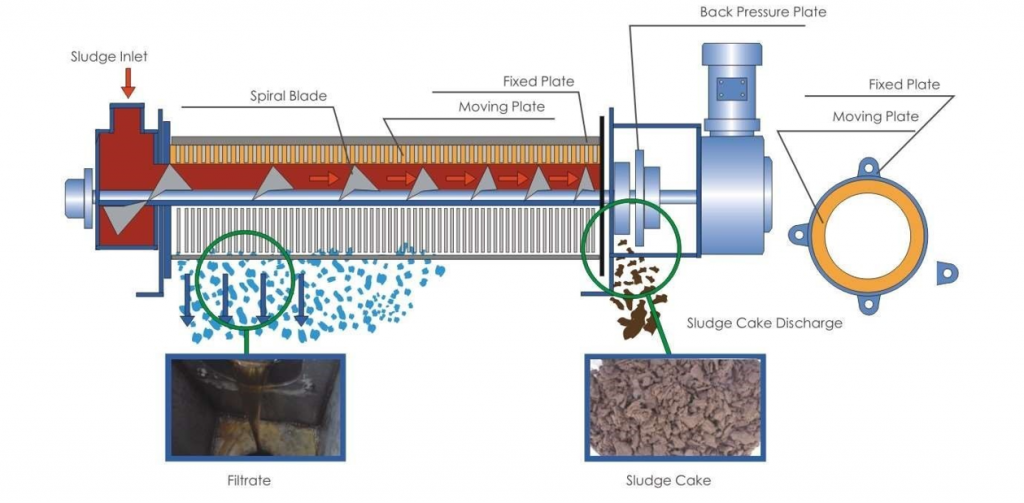

Working Principle

The conditioned sludge flows into the filter chamber from the flocculation tank and is pushed forward to the discharging end. With the gap between the thread of the shaft is getting more and more narrow, the pressure on the sludge is getting higher and higher. Then the water is separated from the sludge and flows out from the gap between the movings and the fixed rings. The movement of the moving rings and the fixed rings cleans the gap between them and prevents the machine from blockage. The filtered sludge cakes are pushed forward by the shaft and finally discharged from the end.

Technical Advantages

For its special structure, accurate design, and processing, Techase® Multi-plate Screw Press is characterized by

following features:

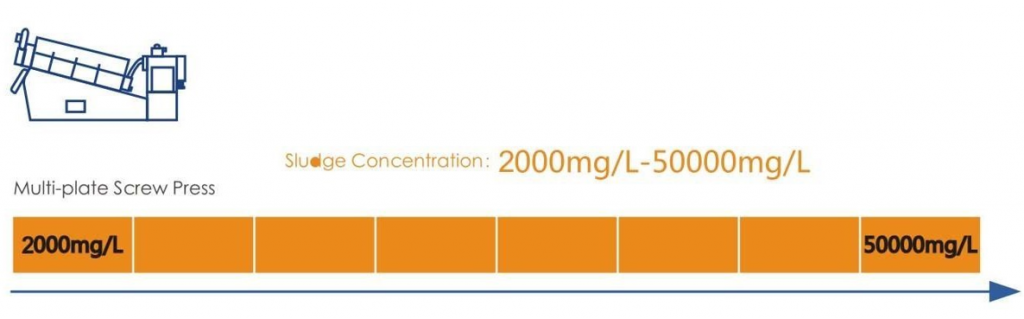

-The exclusive pre-thickening device enables a wide solid concentration ranging from 3000mg/l to 50000mg/l

The thickening zone and the dewatering zone make the machine applicable to both highly concentrated sludge and that with high water content. It’s able to directly treat sludge with a solid content from 3000mg/l to 50000mg/l.

The exclusive pre-thickening device enables excellent performance while dewatering sludge with high water content

- The problems of gravitational thickening disappear and highly efficient thickening is achieved.

- Flocculating and thickening in the same time reduce the subsequent dewatering pressure.

- Adjusting the expansion valve to make the sludge be the best state for dewatering.

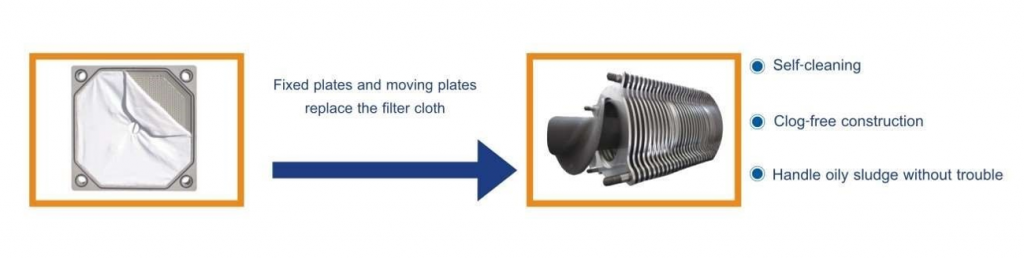

-Fixed and moving plates replace filter cloth, self-cleaning, clog-free, easy to handle oily sludge

The traditional dewatering equipment is easily got blocked while the multi-plate screw press allows continuous operation with no blocking due to that the moving of the fixed rings and moving ring clean itself. Therefore, it’s especially good at oily sludge with excellent performance. Moreover, it doesn’t need additional water for high-pressure clean-

ing so that no smell or secondary pollution will be produced.

The dewatering of the multi-plate screw press relies on the inner pressure of the filter chamber and the rotating speed is as slow as 2–4 r/min. Therefore, its power consumption is as low as 0.01-0.1 kw/h/kg-Ds, only 1/8 of that of belt presses and 1/20 of that of centrifugal machines. In addition, of course, there is little noise. Eventually, the operating cost can be

greatly saved.