LOW TEMPRATURE SLUDGE DRYER

Process

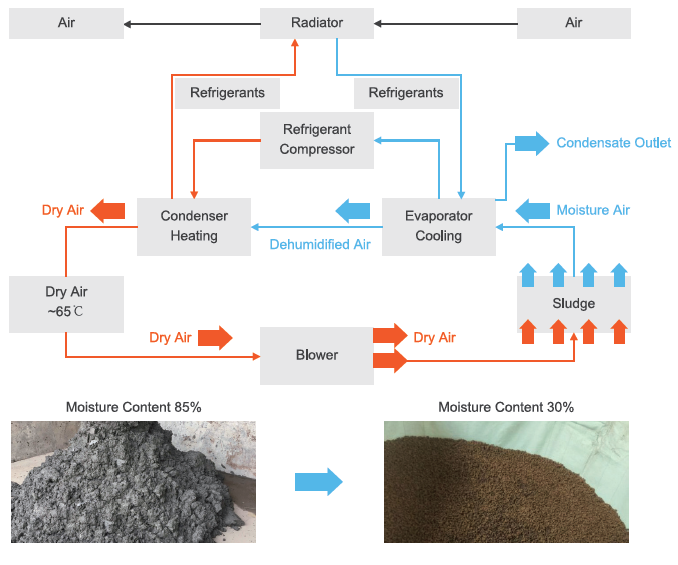

Wet sludge is fed in low temperature sludge dryer after granulation, then the sludge is distributed evenly on the conveying track by sludge arranged distributor so that the moisture can be taken away by flowing air provided by circulating blower and finally

realized discharge of the dry sludge.

After the moisture taken away by the flowing air, the air is condensed at the condenser, the condensed liquid is discharged out of the equipment, and the condensed and dehydrated air is reheated by the heater, then reenter into the sludge, and cycling in this way.

The refrigerant is compressed by the compressor after endothermic process of expansion of cooler, then the heat is released from the heater, the extra heat is removed through the radiator, the refrigerant is subsequently recirculated to the condenser. The radiator in this process can be air-cooled or water-cooled in order to strengthen heat dissipation.

There are multiple sets of temperature, pressure and humidity sensors in the low temperature sludge dryer to monitor and automatically adjust the operation of the device to ensure the dryness of the sludge discharge.

Advantages

Sludge is dried below 70 °C, the particle temperature is lower than 50 °C, no dust, no explosion hazard. Low temperature of sludge discharge (<50 °C), which can be stored directly without cooling.

It adopts advanced heat pump dehumidification technology which is high efficiency and operation reliable. It can directly dry up to 85% moisture sludge to 10% without segmentation; the whole process is automatically controlled, and the moisture content after sludge drying can be adjusted; there is no need for other ingredients, and dry material after discharging has a high calorific value, which is suitable for resource utilization.

Under the premise of meeting the technical requirements of equipment use, we prefer high quality products, and consider the initial investment and post-operational costs of the equipment for reducing the comprehensive cost to the lowest.

Preferred to select the technical process in the “National Key Energy Conservation Technology Promotion Catalogue”, low-power equipment and products in the “National Energy-Saving Product Catalogue”; selected low-temperature fully enclosed drying mode, no odor spillovers, which is no need for complicated deodorizing device.

Applications

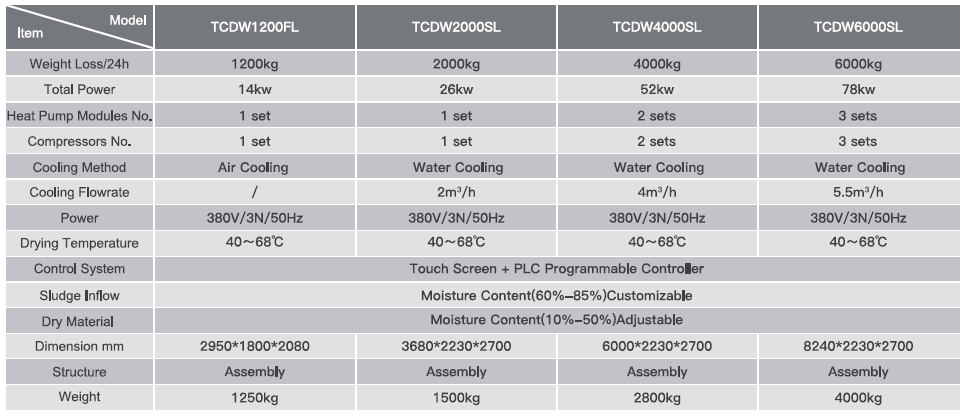

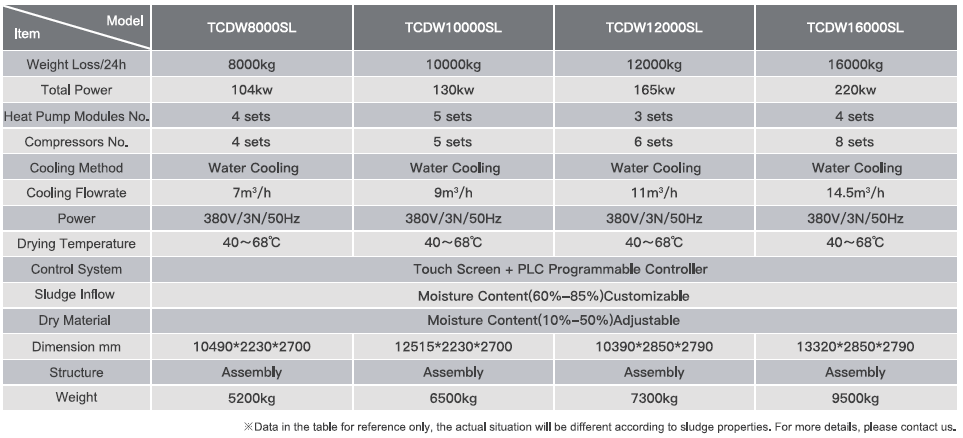

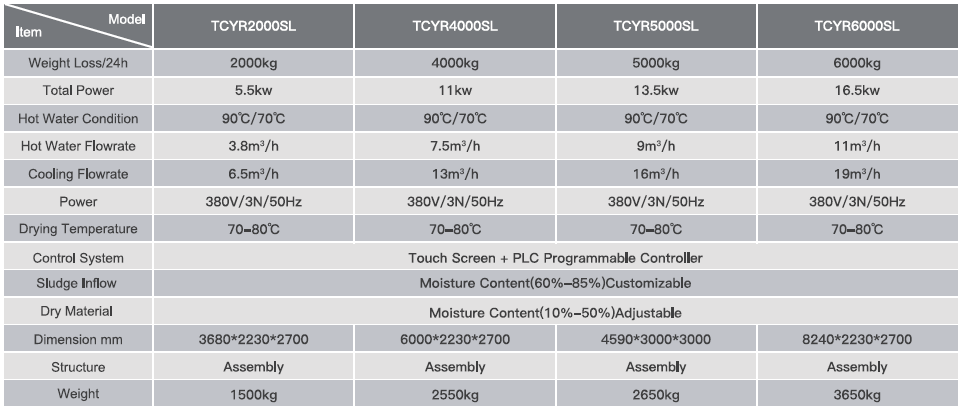

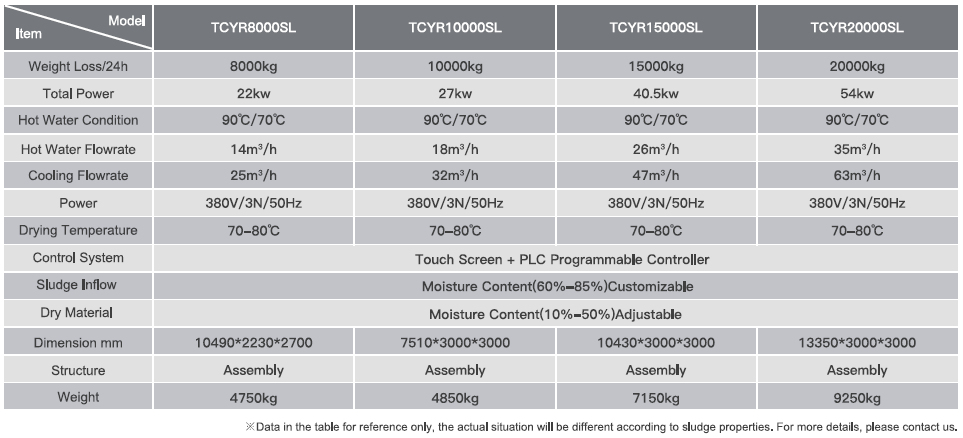

Models with Specifications

Heat Pump Type Low Temperature Sludge Dryer

Waste Heat Type Low Temperature Sludge Dryer

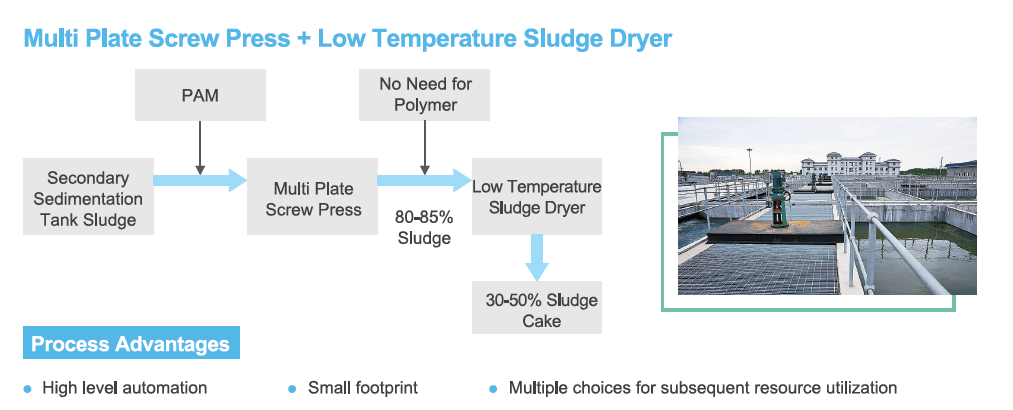

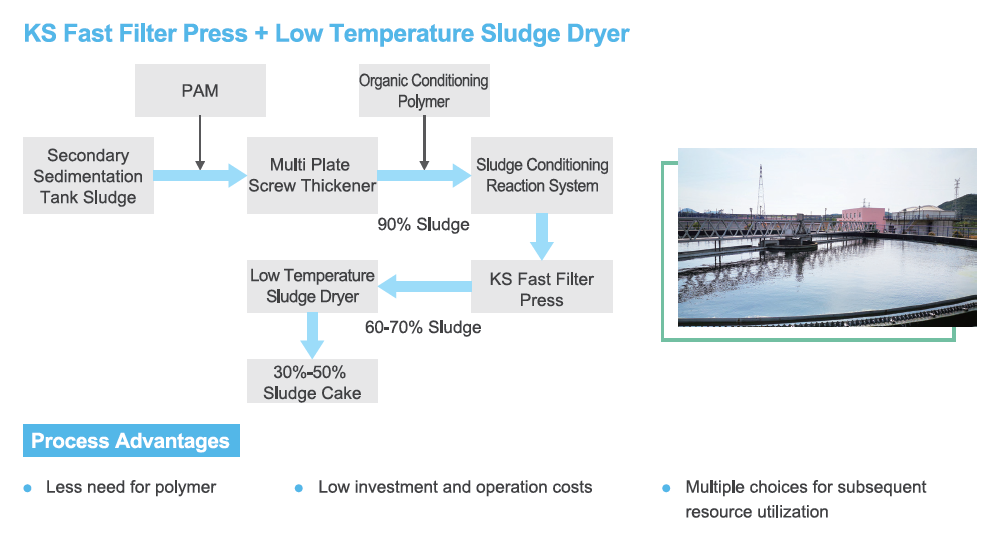

Solutions

Contact us for help?

Contact with us through our representative or submit a business inquiry online.